Aerospace Fasteners Industry Report: Key Players, Innovations, and Regional Trends

Free

The aerospace fasteners industry plays a critical yet often understated role in the global aerospace supply chain. Fasteners — including bolts, nuts, screws, rivets, and specialty locking systems — are essential to the structural integrity, safety, and performance of aircraft. From commercial airliners to defense jets and spacecraft, these components are engineered to withstand extreme forces, vibration, temperature variations, and fatigue over long operational lifespans.

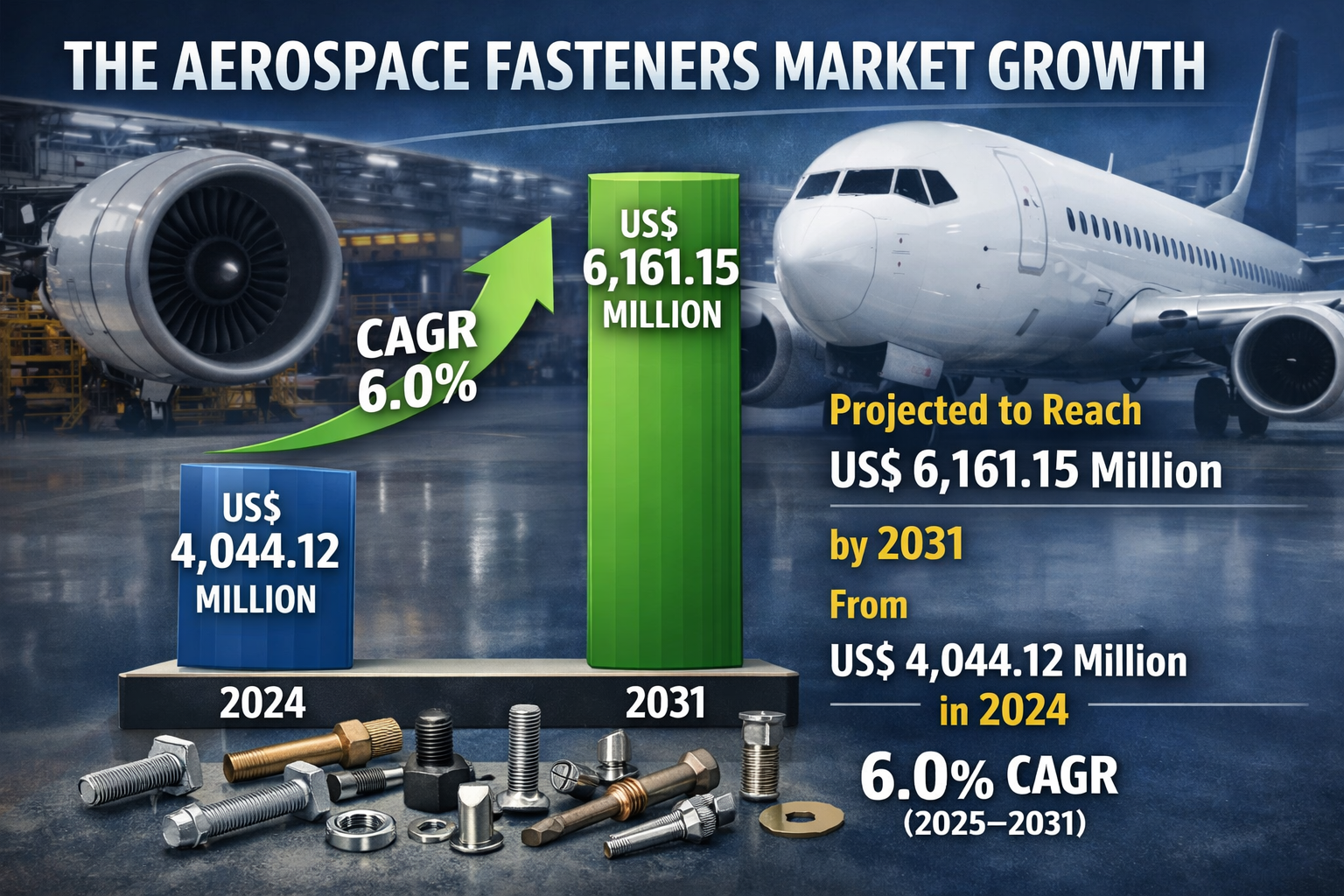

Market Overview

Fasteners in aerospace must meet rigorous standards for strength, durability, and reliability. As a result, materials such as high‑grade titanium, nickel alloys, and advanced aluminum blends are widely used. Growing air travel demand, increased defense spending, and rapid expansion in space exploration have driven consistent growth in this market. Moreover, the rise of next‑generation aircraft and unmanned aerial systems (UAS) continues to create new avenues for fastening technologies.

Request Sample Pages of this Research Study @ https://www.theinsightpartners.com/sample/TIPRE00024654

Key Players

- Precision Castparts Corp.: A leading manufacturer of complex metal components and products, serving the aerospace, defense, and industrial markets with high-performance materials.

- LISI Aerospace SAS: A prominent supplier of aerospace fasteners and assembly solutions, specializing in providing innovative and reliable products for the aviation and defense industries.

- TriMas Aerospace: A global provider of engineered aerospace solutions, offering a wide range of fasteners, components, and assemblies designed to meet stringent industry standards.

- National Aerospace Fasteners Corp.: A manufacturer of high-quality aerospace fasteners and components, dedicated to delivering reliable products that meet the rigorous demands of the aerospace industry.

Innovations Driving the Industry

Innovation within the aerospace fasteners industry has shifted beyond basic mechanical design to encompass materials science, digital traceability, and manufacturing technologies:

- Advanced Materials: The adoption of high‑performance alloys and composite‑compatible fasteners supports weight reduction without sacrificing tensile strength. New coatings and surface treatments enhance corrosion resistance and fatigue life.

- Additive Manufacturing (3D Printing): While traditionally separate from machined fasteners, additive processes are being explored for fastener prototypes, tooling, and complex geometry components that were previously difficult or costly to machine.

- Smart Fasteners: Embedded sensors and connected hardware are emerging trends. These “smart” fasteners can monitor stress, torque, and real‑time performance in critical aircraft structures — contributing to predictive maintenance and improved safety.

- Digital Traceability and Blockchain: Given the high regulatory standards, tracking each fastener’s origin, material batch, heat treatment history, and installation record is essential. Blockchain and digital tagging technologies provide immutable records, simplifying audits and quality control.

- Automation and Precision Machining: Automated CNC (Computer Numerical Control) systems deliver consistency and precision at scale, reducing human error. Machine learning algorithms further optimize production throughput and reduce waste.

Regional Trends

Growth patterns vary by geography, shaped by aerospace manufacturing hubs, government defense budgets, and regional supply chain strategies.

- North America: The United States remains a dominant market, driven by large commercial aircraft production and defense programs. Investments in modernization and space technologies sustain demand for high‑end fastener solutions.

- Europe: Home to major OEMs such as Airbus, Europe exhibits robust demand for aerospace fasteners. Collaborative innovation programs and stringent regulatory standards position European suppliers as quality leaders.

- Asia‑Pacific: Rapid expansion of commercial fleets, particularly in China and India, fuels significant growth opportunities. Local manufacturers are increasingly collaborating with global players to meet rising regional demand while building capacity.

- Middle East and Africa: Although smaller in production scale, these regions are expanding maintenance, repair, and overhaul (MRO) facilities, which increases demand for consumable fasteners and aftermarket components.

Challenges and Opportunities

Key challenges include fluctuations in raw material prices, compliance with evolving certification standards, and supply chain disruptions. However, opportunities abound in aftermarket services, retrofit solutions for aging aircraft, and niches like UAS and space launch vehicles.

Frequently Asked Questions (FAQ)

Q1: What are aerospace fasteners?

A: Aerospace fasteners are purpose‑built mechanical components — such as bolts, screws, rivets, and nuts — designed for aircraft and spacecraft applications where strength, reliability, and weight optimization are critical.

Q2: Why are unique materials used in aerospace fasteners?

A: Lightweight yet strong materials like titanium alloys and high‑grade aluminum are used to reduce overall aircraft weight while maintaining structural integrity under extreme conditions.

Q3: How do innovations like smart fasteners benefit aircraft?

A: Smart fasteners with embedded sensors help monitor structural health, support predictive maintenance, and enhance safety by providing real‑time performance data.

Q4: Which regions lead the aerospace fasteners market?

A: North America and Europe are leading markets due to established aerospace manufacturing sectors, with Asia‑Pacific showing faster growth due to expanding aircraft fleets.

Related Report:

2) Aviation Actuation Market Size

About Us: -

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Also Available in : Korean German Japanese French Chinese Italian Spanish